Guangzhou semi automatic PET bottle making blowing machine

Semi-automatic Blowing Machine

1, Adopt the new-style two-bend arm and four-lug bar to close the mould, the crosss slide is balanceable and fixed.

2, Closing mould and rising bar adopt two-bar together design, favorable for the product-molding.

3, The advanced gas path design: gas inlet one or two path is ok, low pres-sure make the mould close-up,close mouth and rise bars.

4, Microcomputer control is automatic, easy to operate.

5, adjusting automatic, easy to operate.

6, The perform heated by infrared, use temperature control and frequency control to blow the bottle best.

TECHNICAL SPECIFICATIONS

|

ITEM |

UNIT |

TECH ,DATA |

|

FX- 3000 |

||

|

Max .Volumn Of Product |

L |

3L |

|

Production Capacity |

Pcs / h |

1600-1800 Pcs / h |

|

Neck Size Of Product |

mm |

<75 |

|

Useful Area Of Mould Plate |

mm |

340×350 |

|

Max. Mould Thickness |

mm |

180 |

|

Min. Mould Thickness |

mm |

120 |

|

Mould Stroke |

mm |

160 |

|

Clamping Force |

kn |

80 |

|

Stretching Stroke |

mm |

360 |

|

Working Pressure |

Mpa |

≤0.8 |

|

Blowing Air pressure |

Mpa |

≤2.0 |

|

Power Of Main Blower |

kw |

14.6 |

|

Power Of Preheater |

kw |

9 |

|

Weight Of Main Blower |

kgs |

485 |

|

Weight Of Preheater |

kgs |

200 |

|

Measurement Of Main Blower |

mm |

1550×590×1480 |

|

Measurement Of Preheater |

mm |

1800×580×1350 |

|

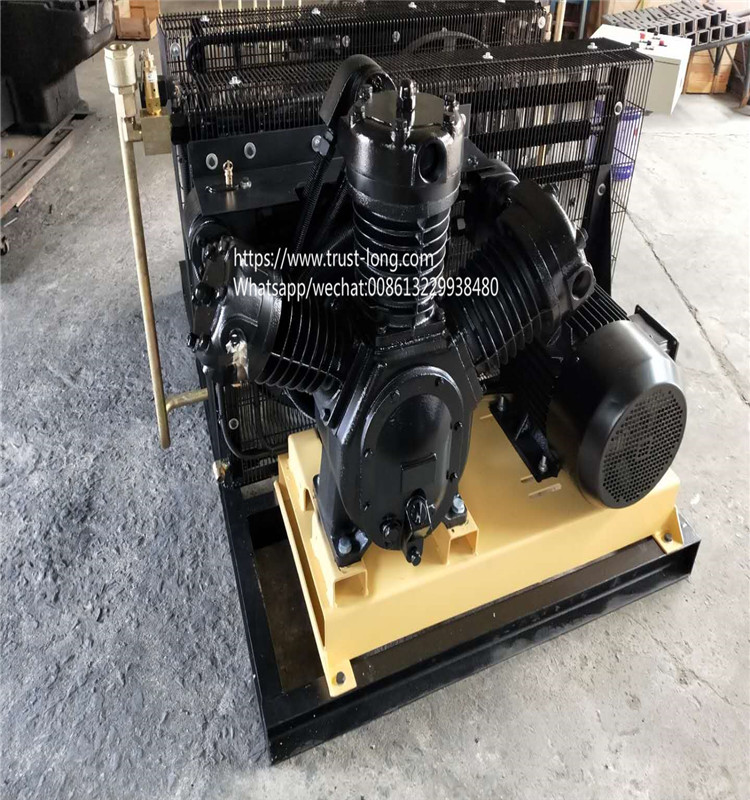

High pressure air compressor(0.7/3.0mpa) |

mm |

1720×760×1320 |